Precision-Made Liners for Leak-Free Performance

Steelhead Composites manufactures both Type 3 and Type 4 pressure vessel liners in-house at our Golden, Colorado, USA facility. Our Type 3 liners are precision-formed from seamless aluminum, while our Type 4 liners are rotomolded from high-performance polymers. These liners form the gas-tight core of our composite overwrapped pressure vessels (COPVs), delivering exceptional durability, chemical compatibility, and long-term reliability across a wide range of high-pressure gas applications. In addition to pressure vessel liners, Steelhead also provides custom rotomolding services for industrial and commercial storage containers.

At the core of every Steelhead pressure vessel is a meticulously engineered liner, purpose-built to contain high-pressure gases safely and reliably. Our liner fabrication process is optimized to meet the most demanding performance requirements across hydrogen energy, aerospace, defense, and industrial gas distribution.

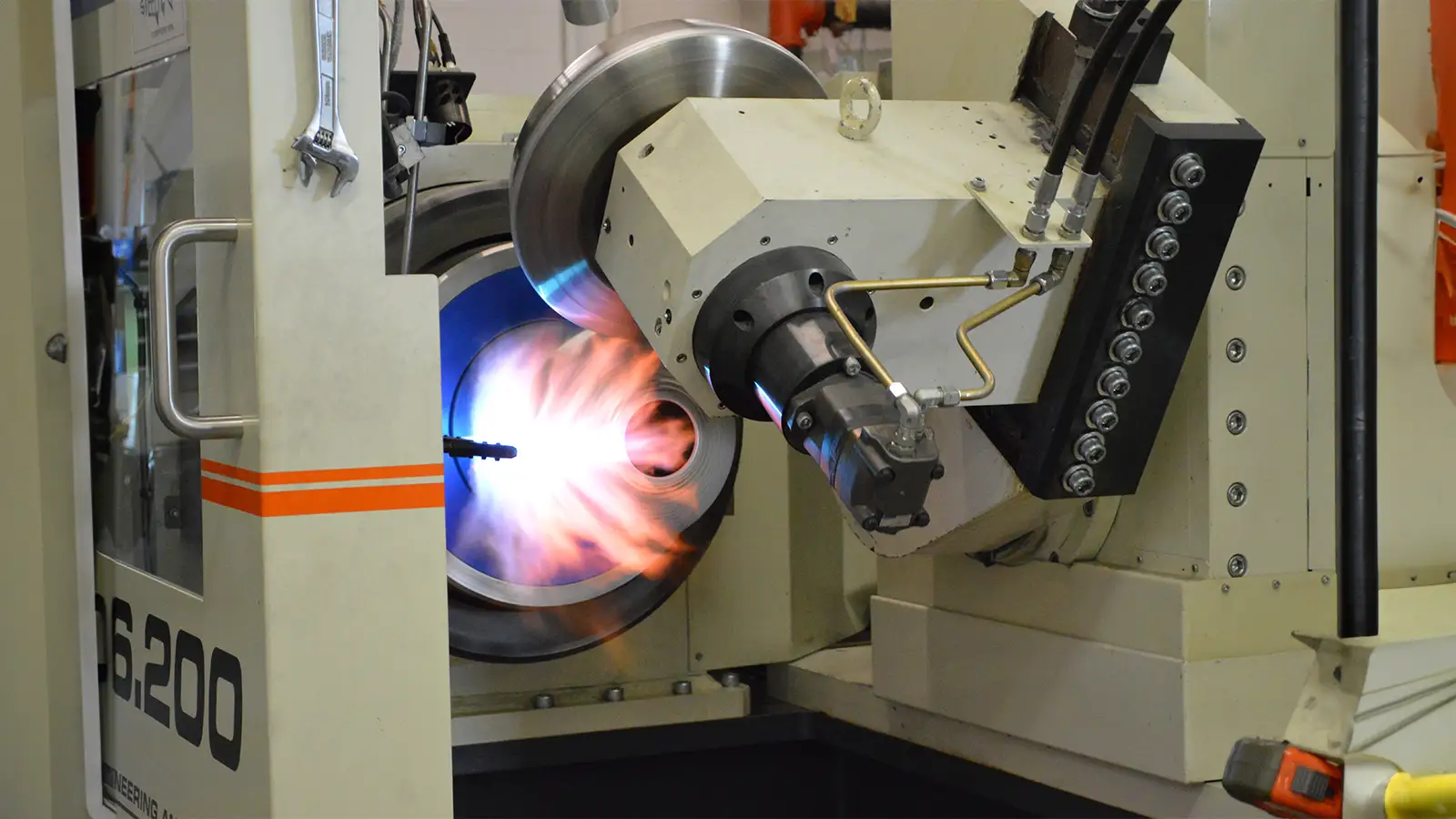

These liners are machined from a single piece of aluminum, eliminating weld seams and potential leak paths. They deliver exceptional structural integrity and are well-suited for applications demanding high burst strength, superior thermal conductivity, and compatibility with both inert and reactive gases.

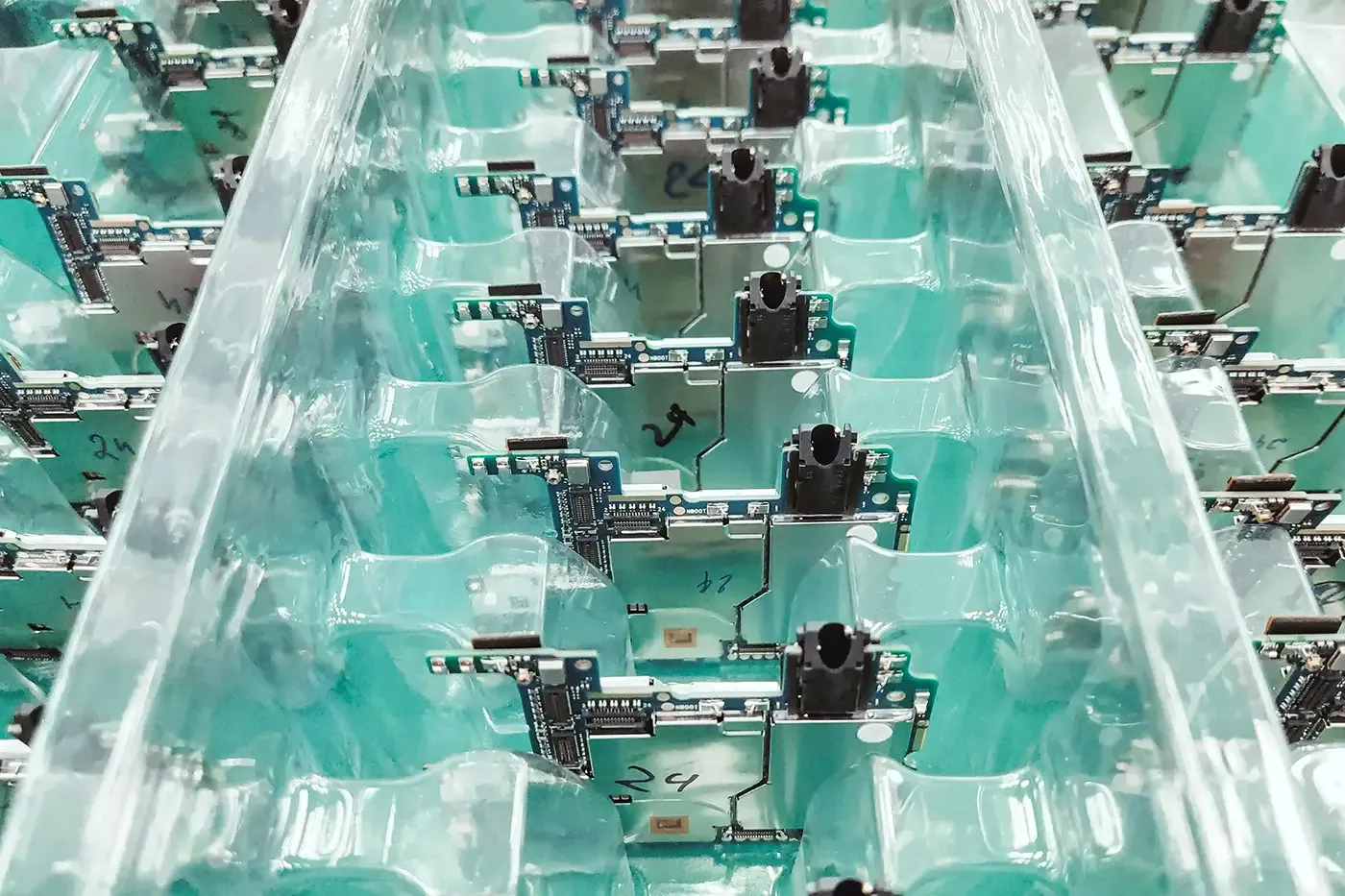

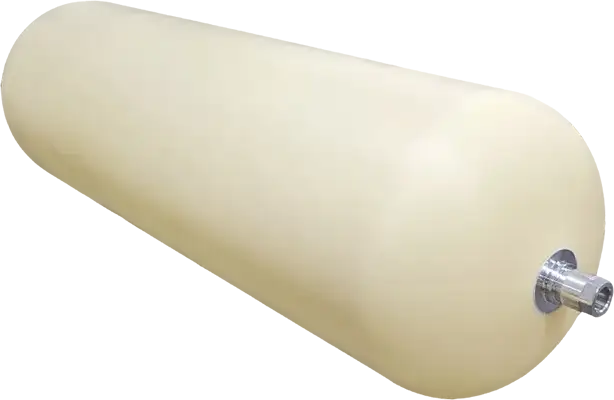

Our rotomolded liners are manufactured from advanced polymers engineered to resist hydrogen permeation and chemical degradation. They are lightweight, corrosion-resistant, and optimized for hydrogen, CNG, and other clean energy applications. The rotomolding process enables complex geometries and precise, consistent wall thickness, ensuring reliable, uniform performance under pressure.

Steelhead’s in-house tooling and fabrication capabilities enable the production of liners in a wide range of shapes and volumes—from compact cylinders for portable systems to large liners for stationary or mobile storage. We collaborate closely with customers to define vessel geometry, port configurations, and material selection, ensuring optimal performance and seamless integration.

Our liners are engineered for compatibility with a wide range of gases—including hydrogen, oxygen, nitrogen, helium, carbon dioxide, and specialty gases. Each liner is designed to ensure leak-tight performance, resist permeation, and maintain structural integrity through thousands of pressure cycles.

Steelhead’s rotomolding expertise extends beyond pressure vessels. We also manufacture custom polymer containers for non-pressurized storage, transport, and industrial applications—delivering the same precision and quality assurance that define our pressure-rated products.