Industries We Serve

Steelhead Composites supports a range of aerospace, space, and defense missions where performance, safety, and reliability are mission-critical.

- Launch Vehicle Propulsion Systems

- Spacecraft Propulsion & Maneuvering

- Satellite Systems

- Unmanned Aerial Vehicles (UAVs)

- Crewed Aircraft & Life Support Systems

- Ground Support & Tank Farms

- Stage Separation & Actuation Systems

- Defense & Military Systems

In aerospace, space, and defense applications, weight, safety, and reliability are mission-critical. Steelhead Composites designs and manufactures advanced composite overwrapped pressure vessels (COPVs) that meet the toughest certification and performance requirements. Our small-format vessels serve UAVs, satellites, and breathing oxygen systems, while our large-capacity tanks support launch propulsion, spacecraft maneuvering, and ground operations.

With expertise in AS9100, ISO, and DOT compliance, we deliver precision-engineered solutions optimized for extreme environments—from launch vibration to orbital microgravity. Whether for propulsion, life support, or stage separation, Steelhead’s vessels combine lightweight design with proven durability, helping our partners reduce mission risk, improve payload capacity, and achieve operational success.

Challenges

Solutions and Recommendations

Steelhead designs small composite pressure vessels engineered for UAVs, satellites, and aerospace platforms—delivering exceptional strength-to-weight ratios, compact form factors, and mission-critical reliability. Our application-specific composite overwrapping and precision port machining ensure seamless integration with propulsion, life-support, and structural systems.

From high-capacity tanks for propulsion systems and ground support to full-scale tank farms, Steelhead provides large composite vessels that enable efficient, high-pressure energy storage for launch and space operations. Accelerated prototype testing—including hydrostatic, burst, fatigue, and environmental validation—fast-tracks compliance with aerospace and defense standards.

Relevant Projects

Launch vehicle propulsion systems

Steelhead’s high-performance composite overwrapped pressure vessels (COPVs) are integrated into launch vehicle propulsion systems where weight, reliability, and pressure containment are mission-critical. These vessels are engineered to withstand extreme acceleration, vibration, and thermal cycling, ensuring consistent fuel or oxidizer delivery during ascent. Their lightweight construction contributes to improved payload capacity and fuel efficiency—key metrics in commercial and government launch programs.

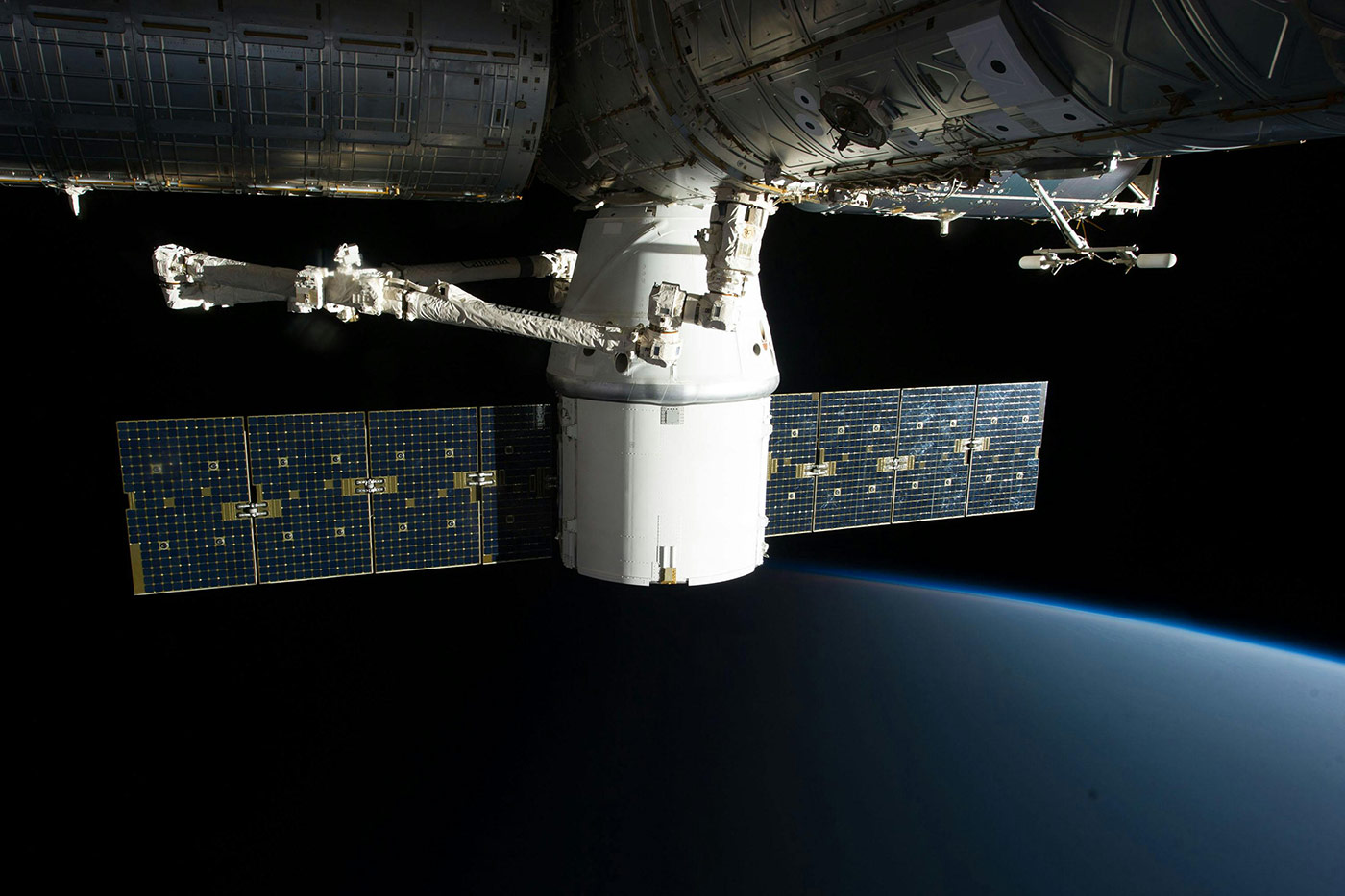

Spacecraft propulsion tanks

For orbital and deep-space missions, Steelhead provides custom-designed COPVs that serve as primary or auxiliary tanks for spacecraft propulsion systems. These vessels are built to operate in vacuum and microgravity environments, with materials and liners selected for compatibility with hypergolic, cryogenic, or pressurized gas propellants. Their proven performance in long-duration missions supports satellite station-keeping, orbital maneuvering, and interplanetary propulsion.

Flight-critical breathing oxygen

Steelhead’s small-format pressure vessels are used in life-support systems for both crewed spacecraft and high-altitude aircraft. These tanks are certified for oxygen service and designed to meet stringent aerospace safety standards. Their compact, lightweight form factor makes them ideal for integration into ejection seats, pilot breathing systems, and emergency oxygen supplies—where reliability under pressure is non-negotiable.

Lightweight one time use pressure vessels

In applications such as stage separation, pyrotechnic actuation, or emergency system deployment, Steelhead supplies single-use COPVs that are optimized for weight and performance. These vessels are engineered for precise burst or discharge characteristics and are often used in expendable systems where every gram counts. Their design balances cost-efficiency with aerospace-grade quality, making them ideal for mission-specific use cases.