Steelhead Composites is not just committed to manufacturing excellence — quality is our essence. We offer an extensive range of testing services, including Pressure Vessel Testing, Cycle Testing, Hydrostatic Burst Testing, and Material Testing Services. These aren't mere procedures; they embody our dedication to delivering products of the highest caliber, ensuring unparalleled safety and precision. Choose Steelhead Composites for industry-leading, thorough testing standards.

Pressure Vessel Testing

- Proof pressures up to an astounding 1634 Bar (23,700 psi)

- Direct Expansion (DE) volumetric data meticulously recorded

- We accommodate vessels up to 457 mm (18 in) in outer diameter and 3353 mm (11 ft) in length

- External pressure testing capability up to 68 Bar (1,000 psi) size limited to 558 mm (22 in) in diameter x 1270 mm (15 in) in length

Cycle Testing

- Precise control with pressures ranging from 200 to 10,000 psi (13 to 689 Bar)

- Achieve 0.25% full-scale pressure accuracy

- Conduct holds from 0 to 60 seconds at target or minimum pressure

- Maximum flow rate of 7.3 gallons per minute (27.6 liters per minute)

- Attain a maximum cycle rate of 10 cycles per minute, with rate dependent on vessel expansion and volume

- Electronic temperature monitoring

- Multiple vessel cycling capability, dependent on vessel size and volume

- High-pressure, high-volume cycle tester (coming Fall 2025)

Hydrostatic Burst Testing

- Pressure range from 0 to 30,000 psi (2068 Bar)

- Burst chamber accommodates a wide range of lengths and diameters

- Strain gage mounting and data acquisition system availability

- Continuous pressure vs. strain data capability

Material Testing Services

- Equipped with a 2,200 lb (10 kN) Instron Load Frame

- Apply strain gauges and achieve high-speed data acquisition

- Conduct mechanical testing compliant with ASTM Standards, including ASTM D4018 and ASTM D638.

- Differential Scanning Calorimetry (DSC) for materials analysis

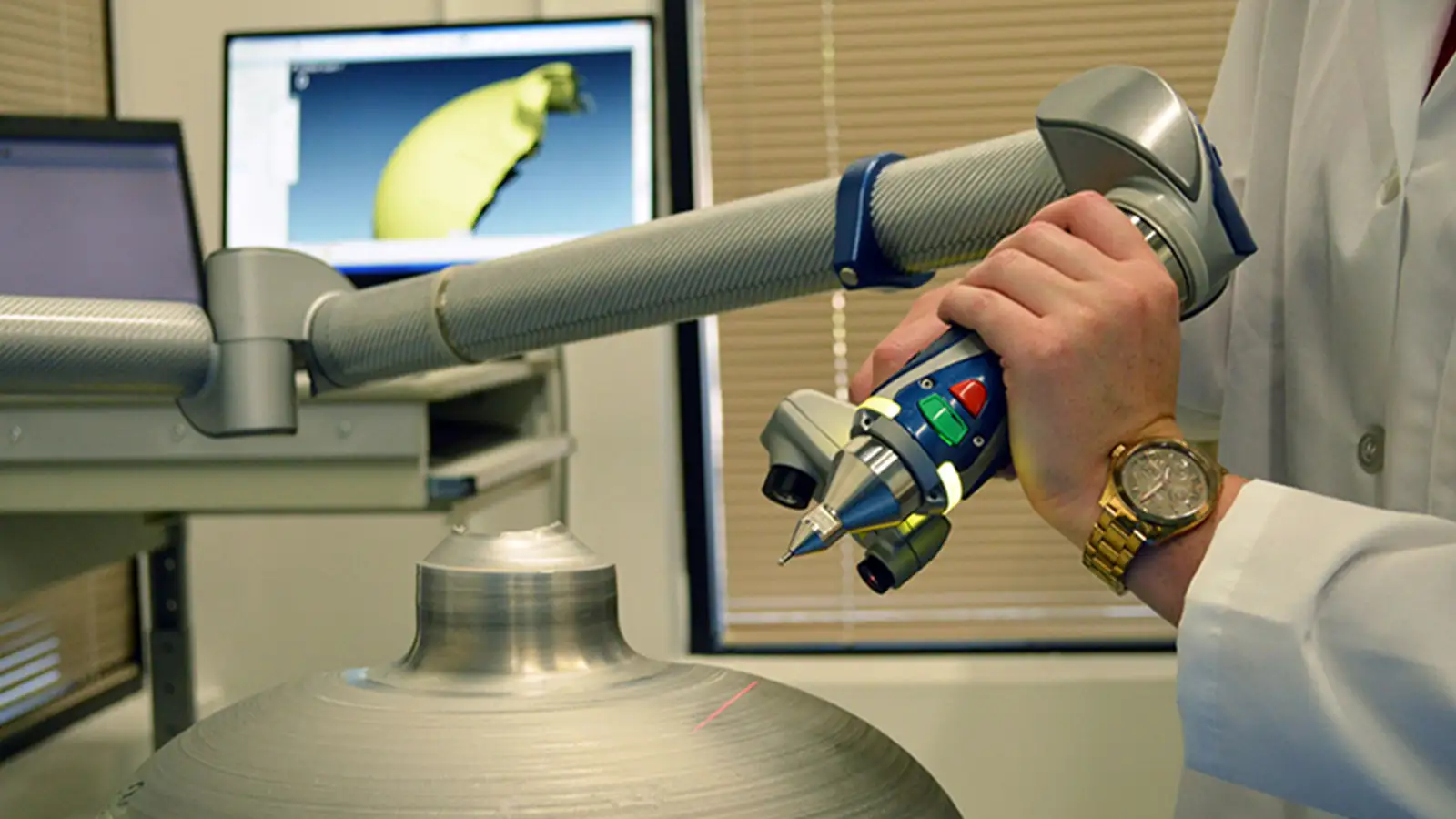

- Utilize a Portable CMM with a Ceramic Probe accurate to 0.0006 in (0.1524 mm)

- Employ a 3D Scanning Laser Line Probe accurate to 0.0014 in (0.03556 mm), ensuring complex geometry verification to CAD standards

Leak Testing

- Tests typically performed using 95% N2 and 5% He gas at vessel working pressure

- Leak test vacuum chamber can accommodate vessels 28 in. (711 mm) in diameter x 8 ft. (2.44 m) in length

- Leybold Trivac D 90L vacuum pump

- LACO and Leybold Mass Spectrometer Leak Detectors capable of measuring Helium or Hydrogen leaks

- Leak rate measurements down to 4.93 x 10-12 scc/s (5 x10-12 mbar L/s)

- Sniffer probe for detecting leaking fittings/joints